GTB® Steel Products

ADVANCED

TECHNOLOGY

FOR INCREASED

EFFICIENCY

GTB® TMT RB500 Advantage

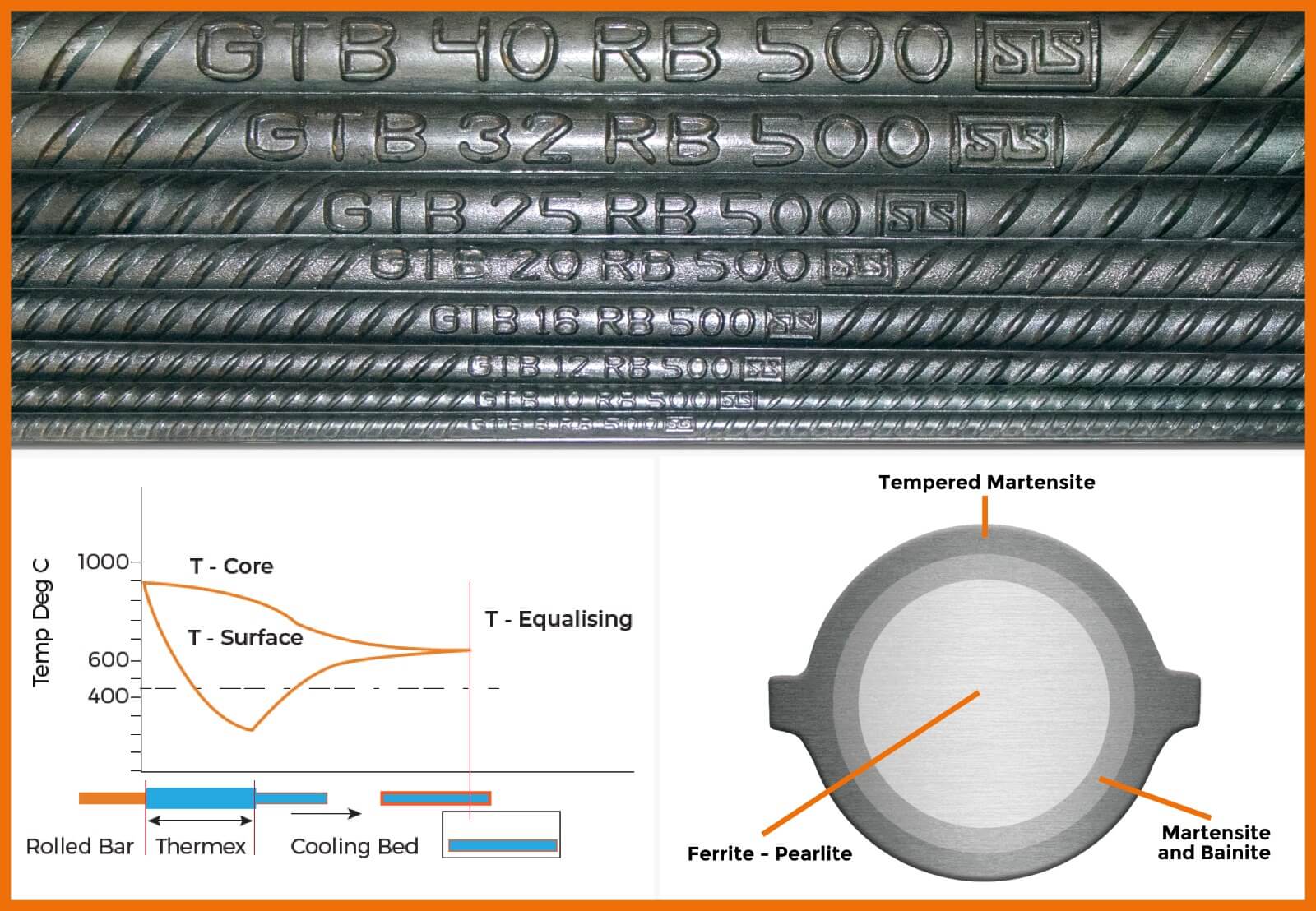

Having redefined steel manufacturing with the introduction of TMT technology to Sri Lanka, GTB® Steel adapted cutting edge Thermo Mechanical Treatment Process (THERMEX) developed by QEK, Germany in manufacturing High Strength Deformed Bars that conform to the requirements of civil engineering needs. The technically superior THERMEX process ensures strength, ductility, weldability and elongation values consistently with every bar GTB® Steel manufactures, providing more value and fulfilling the evolving dynamics of structural engineering requirements.

The strength of pearlitic core and the rough surface of the tempered martensite are maintained at an optimal pressure level of the water in order to achieve the desired standards. As a result, optimum strength, ductility and toughness are provided to the TMT bars.

Due to these advantages TMT bars are widely used in concrete reinforcement structures, industrial structures, high-rise buildings, underground platforms in metro railway and rapid transport systems, bridges, flyovers, dams, thermal and hydro power plants.

Our Range

GTB® TMT RB500 steel bars are available in 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm and 40mm diameters. Our range of profound quality GTB® TMT RB500 steel bars reach the market across Sri Lanka in sizes 6m and 12m. Customisation facility is available for any specific requirements.

Product Specification

| Diameter (mm) | Nominal Cross Sectional Area (mm2) | Mass Per Unit Length (kg/m) | Tolerance |

|---|---|---|---|

| 8 | 50.3 | 0.395 | +/- 6.0% |

| 10 | 78.5 | 0.616 | +/- 4.5% |

| 12 | 113.1 | 0.888 | +/- 4.5% |

| 16 | 201.1 | 1.579 | +/- 4.5% |

| 20 | 314.2 | 2.466 | +/- 4.5% |

| 25 | 490.9 | 3.854 | +/- 4.5% |

| 32 | 804.2 | 6.313 | +/- 4.5% |

| 40 | 1257.0 | 9.864 | +/- 4.5% |