GTB® Steel Process & Quality

Designed for perfect

bonding, lengthened

durability and

heightened safety

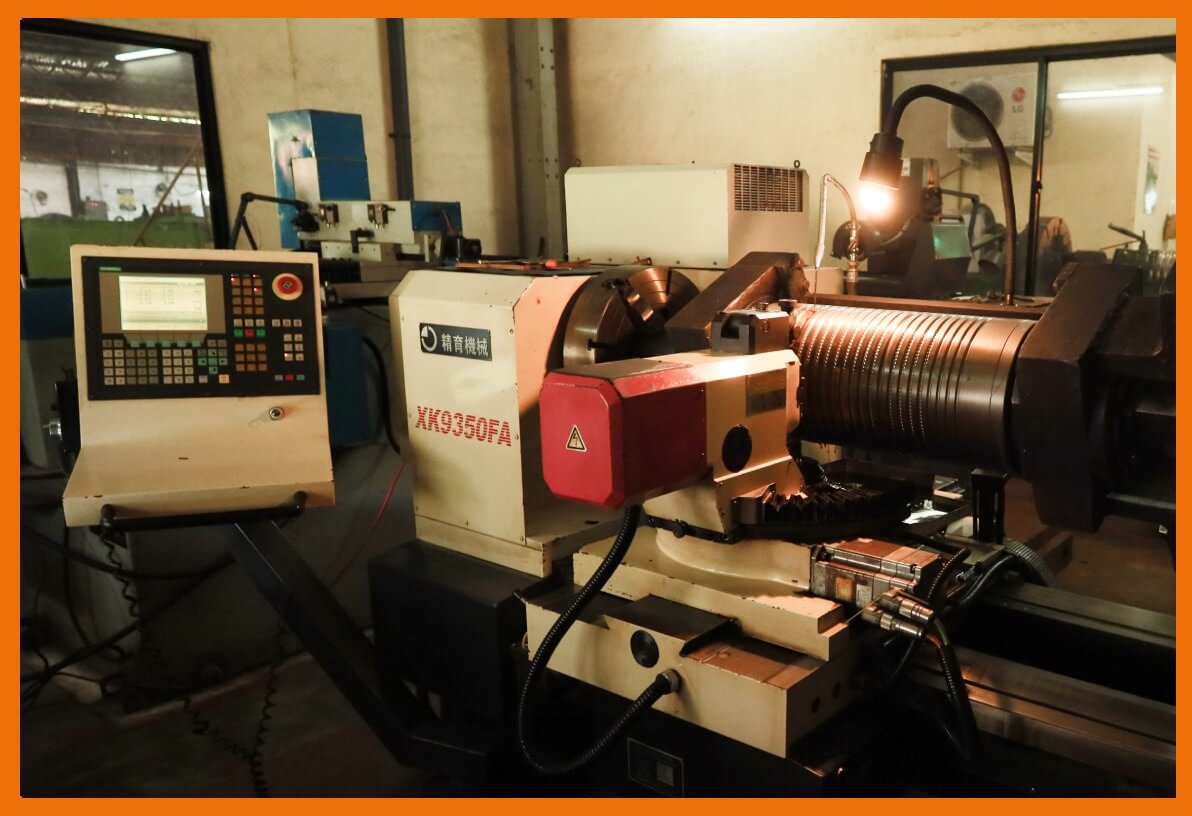

Our Cutting-Edge Process

Microprocessor-based, Programmable Logical Controlled (PLC) re-heating furnace is used for heating billets sourced from prime steel mills and then rolled through a series of mill stands, progressively reducing the section to end size and shape range to produce bars at controlled temperatures. Subjecting to THERMEX Thermomechanical Process immediately after the bars leave their final stand while achieving the desired result of finished GTB® TMT RB500 steel bars of profound quality.

Trust

yourself…

Trust GTB®

Mechanical Properties

| Properties | BS4449:2005 Grade 500B | SLS 375:2009 RB 500 | GTB® TMT Typical Value |

|---|---|---|---|

| Yield Strength (N/mm2) | 500 (min) | 500 (min) | 500 (min) |

| UTS (N/mm2) | 106% of YS (min) | 105% of YS (min) | 620 (min) |

| Total Elongation at Fracture | Not Specified | 14% (min) | 14% (min) |

| Total Elongation at maximum force | 5.0% (min) | 2.5% (min) | 8% (min) |

Chemical Properties

| Element | BS4449:2005 Grade 500B | SLS 375:2009 RB 500 | GTB® TMT Typical Value |

|---|---|---|---|

| Carbon | 0.24% max | 0.24% max | 0.23% max |

| Manganese | Not Specified | Not Specified | 0.50% – 1.00% |

| Sulphur | 0.055% max | 0.055% max | 0.05% max |

| Phosphorus | 0.055% max | 0.055% max | 0.05% max |

Higher Tensile Strength

GTB® TMT RB500 steel bars with a yield point of not less than 500 enables structural engineers designing RCC structures using 8% less steel without compromising on the strength.

More Corrosion Resistance

Precise control of the ThermoMechanical Treatment process results in a uniform and thick Martensite layer free of residual stresses and the dense oxide layer around the bar remains intact in the process. The martensite layer and preserved oxide layer improve the corrosion resistance property of GTB® TMT RB500 bars.

Surpassing Quality Standards

Highest quality standards maintained at GTB® Steel conforms to international standards. Rigorous tests, strictest controls and monitoring of input and production throughout the production process of GTB® TMT RB500 steel bars surpass the standards.

Our Process